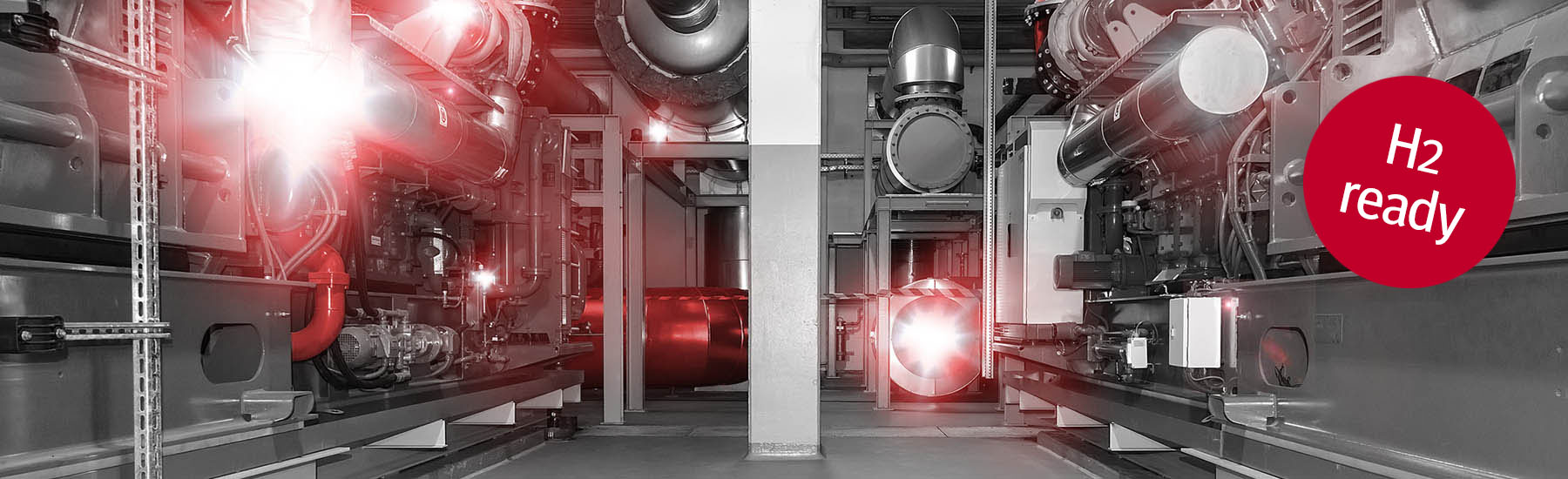

Our E²CON-CHP engine & CHP control unit is H2-ready,

drives gas engines and entire CHP units with admixture or up to 100% hydrogen

in a safely controlled and monitored manner.

Whether for new or updated equipment - this solution allows 100% integration into the overall system.

10 to 20% hydrogen admixture

CHP engine operation with pyrolysis gases from a plastics recycling process given the challenge of ensuring clean mixture and emission control.

Fuel gases containing 50% hydrogen

Europe's largest power plant (25 MW from 9 engines) for converting coke oven gas into electricity has been in operation for over 20 years with a special focus on explosion hazards.

Up to 60% hydrogen admixture

Large-scale plant engineering projects to research robust algorithms for analyzing cylinder pressure in real time and control strategies for operation with varying gas qualities.

Full operation with 100% hydrogen

Engine test benches equipped with controls suitable for series production for the purpose of research and development with transition to worldwide field tests.

For engines and plants to be H2ready, their control systems must be able to receive reliable and accurate combustion data from the individual cylinders so that the engines can run at the load limit with high efficiencies while also being protected against overload. This is where our AVAT technology modules for efficient combustion control come into play.

The devices calculate the necessary parameters based on the complex sensor signals and then transmit them directly to the gas engine control unit. A direct line of communication between the components and the control system allows the combustion process to be regulated so as to ensure optimum efficiency while complying with legally prescribed emissions.

Knock Detection

The structure-borne noise pick-ups, commonly known as knock sensors, have been used for many years for the detection of combustion knock. E²KNOCKCON modules can also detect misfires individually on the basis of combustion noise and communicate the information direct to the engine controller.

Cylinder Pressure

Measuring the pressure pattern in the cylinder is the method of choice for acquiring precise characteristic values for combustion. E²PRECON modules computes power, peak pressure, knocking intensity and the temporal combustion pattern for each cylinder and each individual combustion event.

Our components can also be used as individual modules with third-party controllers and thus efficiently regulate hydrogen admixtures in the future. We also offer a highly optimized solution for this use case in combination with our multivariable controller E²CORE-control.

Let's talk!

New technologies always bring questions along. About integration, about control methodologies, about the use of hydrogen in the energy supply environment. he best way to discuss the individual specifics is in a personal conversation.

Call us without any obligation or use our form below - we'll be happy to share our H2 knowledge with you!

![[Translate to English:] AVAT Wasserstoff H2 Motor & BHKW Steuer- und Regelungstechnik](/fileadmin/_processed_/9/1/csm_AVAT_Wasserstoff_BHKW_3099f1034e.jpg)

![[Translate to English:] Anlagen-Eignungstest mit dem Quick-Flexcheck](/fileadmin/_processed_/6/5/csm_AVAT_Einheitenzertifikat_Kontakt_Picto_rot-weiss_73beac844b.png)