The sustainable production and widespread use of hydrogen is becoming more and more important. With regard to regional heating for neighborhoods, local public transport and energy-intensive industries such as chemicals and steel, hydrogen is seen as the climate-friendly energy solution of the future. National hydrogen strategies therefore promote the use of H2 technologies for energy supply. These include measures to improve the technical maturity of power units and their suitability for series production as well as measures to increase reliability, safety and efficiency during production and use.

In all these measures, intelligent control engineering combined with AI models, algorithms and generation and load forecasts plays a central role. This is why numerous projects are currently emerging across Europe, all of which have one goal: to optimize the production and use of "green" hydrogen as an energy carrier in such a way that national climate targets are achieved, fossil fuel independence is promoted and H2 offers an economic gain.

Electrolyzer

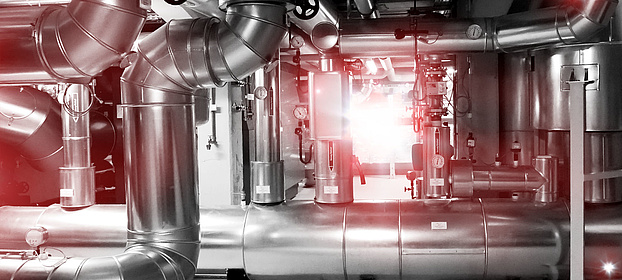

Electrolysis is a CO2-neutral technology that is becoming an important part of our Energy Systems. It is therefore critical to find the best possible means of integrating electrolyzers into the decentral power plant controller as well as the necessary sector integration.

CHP

Our E²CON-CHP engine & CHP control unit is H2-ready, drives gas engines and entire CHP units with admixture or up to 100% hydrogen in a safely controlled and monitored manner. Whether for new or updated equipment - this solution allows 100% integration into the overall system.

Energy Station

Our higher-level energy center control system, the SE²MASTER, ensures that all components in an energy station, which includes e.g. the electrolyzer, CHP unit, other generators as well as storage units and energy consumers, work perfectly with each other.

Optimization

Hydrogen produced from renewable energies is still not competitive without subsidies. With AI-based forecasts and fully automated plant optimization - for example with our SE²OPTIMIZER - the overall system also becomes an economic success right from the project start.

Power-to-gas technology makes it possible to store regeneratively generated green electricity as hydrogen through electrolysis. Afterwards the hydrogen (instead of the natural gas) in CHP units can be converted back into climate-neutral electricity and heat or cooling during periods of low light.

Our E²CON-CHP engine & CHP control system comes with all the modules necessary for safe and cost-efficient operation from 0% to 100% hydrogen:

- Engine protection against knocking and premature or spontaneous ignition

- Combustion control based on structure-borne noise or cylinder pressure and control strategies for operation with varying gas qualities

- Multi-variable controller for quick regulation of mixture, ignition timing and power

- Regulation for compliance with the NOx emission limits with varying H2 amounts

- Cloud-based data processing for predictive servicing and power plant support

10 to 20% hydrogen admixture

CHP engine operation with pyrolysis gases from a plastics recycling process given the challenge of ensuring clean mixture and emission control.

Fuel gases containing 50% hydrogen

Europe's largest power plant (25 MW from 9 engines) for converting coke oven gas into electricity has been in operation for over 20 years with a special focus on explosion hazards.

Up to 60% hydrogen admixture

Large-scale plant engineering projects to research robust algorithms for analyzing cylinder pressure in real time and control strategies for operation with varying gas qualities.

Full operation with 100% hydrogen

Engine test benches equipped with controls suitable for series production for the purpose of research and development with transition to worldwide field tests.

Our SE²MASTER ensures seamless interaction between all the components and sectors of an energy center, including wind farm, electrolyzer, CHP, storage units and power consumers. This is especially the case when hydrogen comes into play.

- Integration and monitoring of electrolyzers, H2 storage and H2 power generation

- Easy configuration instead of complicated programming

- Storage management and optimization of energy flows

Our higher-level energy center control system can also be used for this in the usual way and makes it extremely easy to integrate the electrolyzer and all other units into the power plant. Integration into the control system or existing grid systems is also quick and easy.

Pure rocket technology? Not at all!

We demonstrate this in the first flagship projects.

For example, the research project of the German Aerospace Center (DLR) and ZEAG AG in Heilbronn, Germany. Green hydrogen has been produced from wind power at the new plant there for almost two years now. It is stored and then tested to determine which applications of hydrogen can be used with 99.99% purity.

- Green hydrogen for the engines of the ARIANE space rockets

- Green hydrogen for two CHP units for heat and power supply

- Green hydrogen for cars, delivery traffic and buses in the region

Worthy of an award, isn’t it? More details about our H2-flagship project here ...

The cost of hydrogen from fossil fuels is still significantly lower than the cost of renewable power generation. However, the series production costs of electrolyzers will continue to fall and CO2 emission taxes will rise more sharply. This will make renewably generated hydrogen more attractive and competitive in the long term.

With AI-based forecasts and fully automated plant optimization using our SE²OPTIMIZER plant optimizer, we are already working to improve economic efficiency in projects and the operation of power plants, making them attractive much sooner.

- Takes into account electrolyzers, H2 storage and H2 power generation

- Fully automated, exchange price-based optimization

- Ensures generation from 100% renewable energies

- Combines power generators and consumers into virtual power plants

The know-how we have gained through decades of building a wide variety of hydrogen applications is not the only thing that makes us an interesting partner for H2 projects. We are also specialists in the engineering of smart MSR technology for sustainable energy management, and our expertise puts us right at the center of all industry players. We provide the bridge between process and application and between application and power plant. We work on both sides, which, given our experience implementing comparable projects, allows us to develop the right control system with all functions for operation and service and make it available in a modular package.

Technology & Partnership

Better modular, instead of always individual.

We always start from the power plant side when it comes to the control and regulation of components such as gas engines, wind turbines, PV, electrolyzers or storage systems for power generation and distribution. Designing interfaces has been our core competence for over 30 years. This means that for control and regulation, we always focus on the best possible integration into the overall system, so that we can ensure success for all parties when future-oriented plants and technologies are put into operation.

Smart. Innovative. Cross-sector.

Do you have any questions about the integration, control or use of hydrogen in the energy supply environment or about our cross-sector solutions to ensure safe operation in power plants, control technology or optimization for the best possible revenues? Call us or fill out the form!