Superordinate control of multi-valent

heating centers and hybrid energy stations

Wherever energy is generated, the SE²MASTER is at the center - the freely configurable controller for higher-level control of iCHP and CHP systems, such as hybrid energy centers, multivalent heating stations or complex CHP plants in districts, clinics, swimming bathes or in the industrial sectors.

With the SE2MASTER - Energy Station Controller - you get a control system with which you can operate and visualise the complete plant. Generation units such as CHP units, electrolysers, heat pumps, solar thermals and geothermal systems as well as electric heaters or boilers, but also electricity/heat storage systems, network pumps and valves are brought together and perfectly coordinated, taking into account the hydraulic interconnection. And, like the interplay in a large orchestra, harmoniously conducted.

Configurable instead of programmed - the SE²MASTER can be configured for simple as well as for complex energy plants and systems equally quickly and expanded at any time - up to the control of heat networks with feed-in from several energy centers. All data is available at any time via standard interfaces - our SE²OPERATOR heat grid control system, for example, can automatically take over the entire configuration of the SE²MASTER. This significantly reduces the effort required for setup and visualization.

Highlights AVAT SE²MASTER

- Superordinate control of hybrid power stations including storage management and grid feed-in control

- Convenient configuration and automated connection to the grid control system

- Interfaces to the energy management system and the virtual power plant

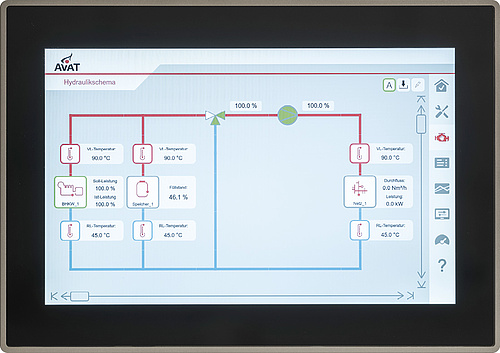

- Color touch panel, which can be accessed directly or remotely, ensures optimal ease-of-use down to the individual controller

- Monitoring functions, fault annunciation system

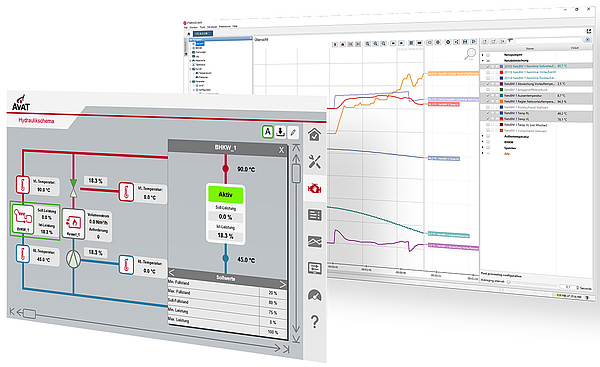

- Visualisation of the hydraulic plan

- Trend curve representation

- Extensive parameter setting potential

Configurable

The configuration replaces the usual individual programming of the control. In this way, the system components are implemented intuitively. Time and thus cost savings are guaranteed, and the implementation risk is significantly reduced.

Modular

The modularity of the plant control system is designed in such a way that, with the help of the option selection, only the necessary components are added exactly as required. The system is therefore scalable to a wide range of plant sizes and can be expanded as required.

Economical

Cost and energy efficiency with the greatest possible flexibility. The coordinated generator, storage and heat distribution management ensures optimum operation. Heat losses and own power requirements are noticeably minimized.

Standardized

The use of robust standard controllers and components as well as a manufacturer-independent, internationally standardized programming environment opens up freedom and at the same time creates future security.

Consistent

Whether in the direction of heat transfer, to the control technology or to the virtual power plant - the coordinated structures within our products create supply security. The graphical touch interface offers good operating comfort and a clear image of the entire plant.

Sustainable

Maximum use of energy sources with maximum generation efficiency, due to the seamless integration of generators and energy storage, enables the optimal balance between energy generation and energy consumption.

Unique visualization

All settings via color touch panel

Direct control and regulation of individual generators and aggregates

Detailed visualization of the hydraulic scheme

Display of actual values and trend curves

Administration of access authorization for customer and service

Configuration and software updates via USB or Ethernet

Optional access via web browser or control system

Standardized processes, simple handling, faster project cycles, and systems that are coordinated and scalable in detail will be the decisive factors for economic success in the sustainable energy industry in the future. The S²CONDUCTOR already provides all the technical prerequisites for this today.

![[Translate to English:] AVAT SE²OPERATOR Leitsystem](/fileadmin/_processed_/d/6/csm_AVAT_Smart-Energy_SE2OPERATOR_Energieleitsystem_3125aaf9fd.jpg)

![[Translate to English:] AVAT SE²BASE Übergabestationsregler](/fileadmin/_processed_/d/2/csm_AVAT_Smart-Energy_SE2BASE_Uebergabestationsregler_4c082d56ec.jpg)