Marine Dual-Fuel & LNG

engine control system

E²CON-M

To meet strict emission limits, shipping industry is turning to gaseous fuels. For the best control of engines in marine propulsion and onboard power generation we support our clients with a full line of vertically integrated control and automation technology solutions including hardware, software and, importantly, expert consulting.

Optimized output and reliability under fluctuating or uncertain gas quality is the essence of gas engine control. It can only happen if the control system is precisely adapted to the engine and application. With E²CON-M you will quickly get the controller you need for marine gas or dual fuel engines. A modular system of proven elements, E²CON-M is highly adaptable. In close cooperation with the client, we can rapidly develop a customized control system for every marine medium-speed engine. The result: maximum performance, efficiency and reliability even under high load and rough conditions.

Advantages AVAT E²CON-M

- A control system for both the engine and the auxiliaries

- Rapid engine run-up to operating speed

- Compact system layout

- Powerful built-in diagnostic tools

- Approved control hardware components

- Flexibly expandable and adaptable at all times

- Spare parts availability over many years

- Proven technologies from the large engine field

- High fuel efficiency at optimum emission levels

- Support for engine type approval process

Safety concept

Based on our unique system integration platform for gas and dual fuel engines, E²CON-M is completely flexible, scalable and open to any kind of extension. Functions, modules and subsystems form one unit with a powerful user interface.

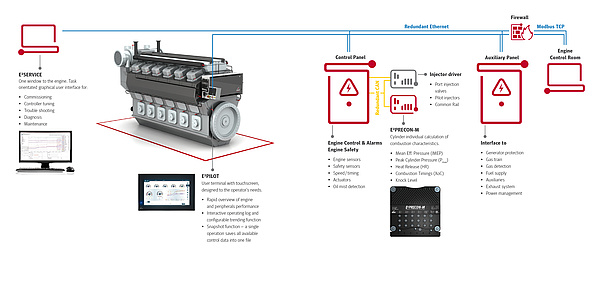

E²CON-M is integrated into the ships automation and consists of three units. The control panel with an engine control and alarms module combined with an engine safety system, the auxiliary panel and a technology component to control combustion characteristics. The control architecture is based on an industrial controller. All modules and devices operate according to the principle "smart sensor" and "smart actuator". They deliver pre-processed information and are controlled and configured by the PLC. All control and monitoring functions access the same data and thus all data is usable in the total system and is displayed on the user interface.

The reinforced cabinet of the control panel and the combustion control unit are vibration-damped mounted on the engine. Wiring of sensors and actuators is directly connected to terminal blocks inside the control panel. As third unit the auxiliary panel is placed away from the engine to simplify wiring of auxiliary inputs and outputs. Redundant Ethernet and CAN connections ensure high operational safety.

Functions

- Fuel-sharing mode

- Diesel-gas switchover even at high load operation

- System fulfills requirements for multi engine power generation

- Cylinder pressure based engine control and monitoring

- Balancing strategies based on identified combustion parameters

- Integrated auxiliary control

- Control and monitoring of fuel supply

- Redundant standard data interface to vessel control

- One powerful remote service tool for direct access to the engine

- Acquisition and processing of relevant KPIs

Marine Type Approvals

Our company's quality management and development processes are subject to external audits on a regular basis. Thus the E²CON-M components are type-approved by major marine classification societies.

With our engine know-how and experience based on years of working and developing together with major engine builders, we are able to fully support our clients in the process of engine type approval and accompany their project from the drawing board to its sea trials.