Plant optimization is actually a simple task. With surpluses, you can achieve either additional revenues when electricity prices are high and lower consumption costs when electricity prices are low. Actually. But when is the right time for either of these two actions? When can plants do this without neglecting actual tasks? And how do you adjust the timetable to your plant in advance?

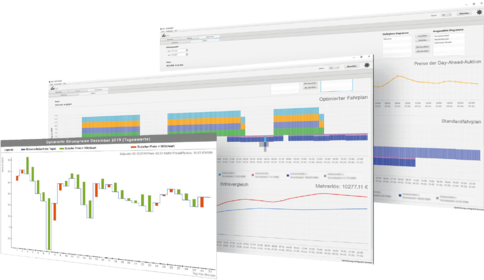

The solution: the AVAT SE²OPTIMIZER

Our plant optimizer provides a unique solution for cost-reducing and revenue-increasing operation. By using weather and power price forecasts as well as its own AI-forecasted demand analysis, this solution optimizes operation and makes the previously unused flexibilities of CHP systems or iCHP systems economically viable.

More information on the requirements and the technology can be found in the FAQ

FAQ

What kind of CHP plants can benefit from this type of operation optimization?

Do you operate a combined heat and power plant (CHP) or an innovative combined heat and power plant (iCHP)? Whether your plant uses iCHP, CHP or renewable energy or is no longer eligible for subsidies - the combination of plant operation optimization via direct marketing is your key to economically optimized plant operation in the future. Ideally your plant has a minimum total electrical output of 500kW, is designed for a maximum of 6000 full hours of operation per year and uses a fuel made from (raw) biogas, biomethane or natural gas. It should also have a redundant heat supply and an adequately sized buffer storage tank. We’ll take care of everything else!

What approach is used for the optimization process?

The approach is to take advantage of the unused flexibilities your plant offers as a result of your heating and/or gas storage tanks and other factors. Your own heat and electricity needs always have the highest priority, of course. With the help of forecasted weather data, historical energy demands and technical restrictions, the intelligent software of the SE²OPTIMIZER uses AI (artificial intelligence) to predict which mode of operation covers your future needs. In essence, an approach that minimizes all costs. It also allows you to achieve significant additional revenues even after your plant is no longer eligible for subsidies.

What technology is used for CHP plant optimization?

Optimization involves installing our smart SE²OPTIMIZERS at the plants, which are used to create operating timetables based on local weather and electricity price forecasts and their own AI-forecasted demand analysis and can be connected to almost any trading platform for subsequent marketing. Whether plant operation is optimized for self-generated power or for electricity prices, a switch that can be made at any time, the final decision always lies with the operator. The same applies for the operating data. More information can be found in our SE²OPTIMIZER brochure.