After a lightning strike with massive damage to the CPU-1, operating computer and speed sensor card of the TEM-Evo motor controller, a conventional repair was disproportionate for the operator, Milchquelle Stüdenitz in Stüdenitz-Schönermark. Modernizing the control system in order to be equipped for the future requirements of the energy transition proved to be the more economical solution. The system is a combined heat and power unit (CHP) from the manufacturer FA. Regio. The CHP unit is installed in a container and was commissioned in 2007. A TCG 2016 V12 is used as the gas engine, which was originally controlled via the TEM-Evo engine control system.

The challenge

One of the biggest challenges was to limit the downtime of the supply system to a maximum of three days. In addition, the new engine control system E²CON-TE (more information here ...) had to be seamlessly integrated into the existing CHP and biogas plant control systems. The 3964R serial protocol had to be used for this. A widely used but outdated communication interface that E²CON-TE also supports in addition to today's standard protocols. The E²CON-TE modernization system can also be used for all TEM-Evo variants and versions from 1996 to the present day.

Our Solutions

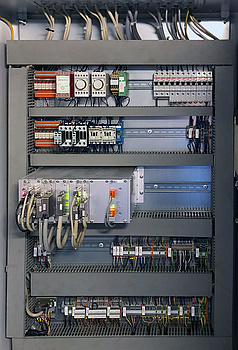

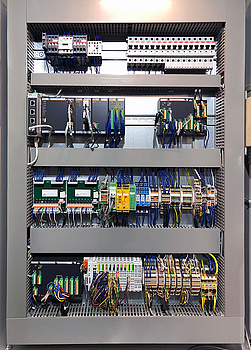

The old mounting plate with the TEM-Evo control unit was completely removed from the control cabinet and simply replaced with a new, preconfigured E²CON-TE motor control unit with 4 screws. It goes without saying that no cable sets need to be replaced. Thanks to this precise fit, the time and effort required for commissioning has been significantly reduced. Another time-saving advantage with E²CON-TE is the option of parameter conversion: all parameter designations and numbers are identical to TEM-Evo. The existing I/O Controller 2 was initially retained and then upgraded with the current I/O Controller 3 model.

The customer's E²CON-TE uses:

- E²CORE-control: highly-dynamic, multi-variable controller for simultaneous control of speed, power and mixture.

- E²KNOCKCON-c: for reliable cylinder-specific knock and misfire detection

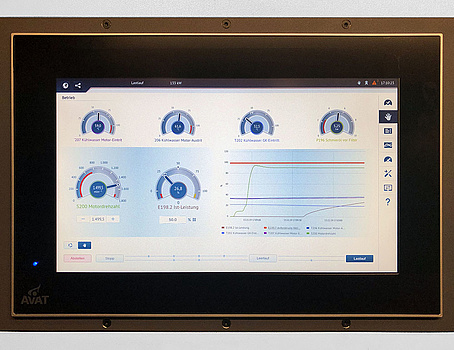

- E²PILOT: operating terminal with 15" capacitive touch screen, customized for the system operator.

- E²SERVICE: our service visualization tool for optimal parameterization and system diagnosis with interactive operating log and configurable trends

- AVAT VIRTUAL SERVICES: for remote access, fleet management and predictive maintenance

- NOx regulation: in accordance with the 44th BImSchV (Ordinance for the Implementation of the Federal Immission Control Act )

The customer benefit

The entire system was back in operation by the late afternoon of the second day. The E²CON-TE plug & run modernization system not only paid off in terms of time, but also financially, making the conversion a worthwhile investment for years to come. The company ServioTec (www.serviotec.com) from Henningsdorf, which has already successfully carried out more than 15 modernizations with E²CON-TE, ensured that all the conversion work ran smoothly.